- Industries

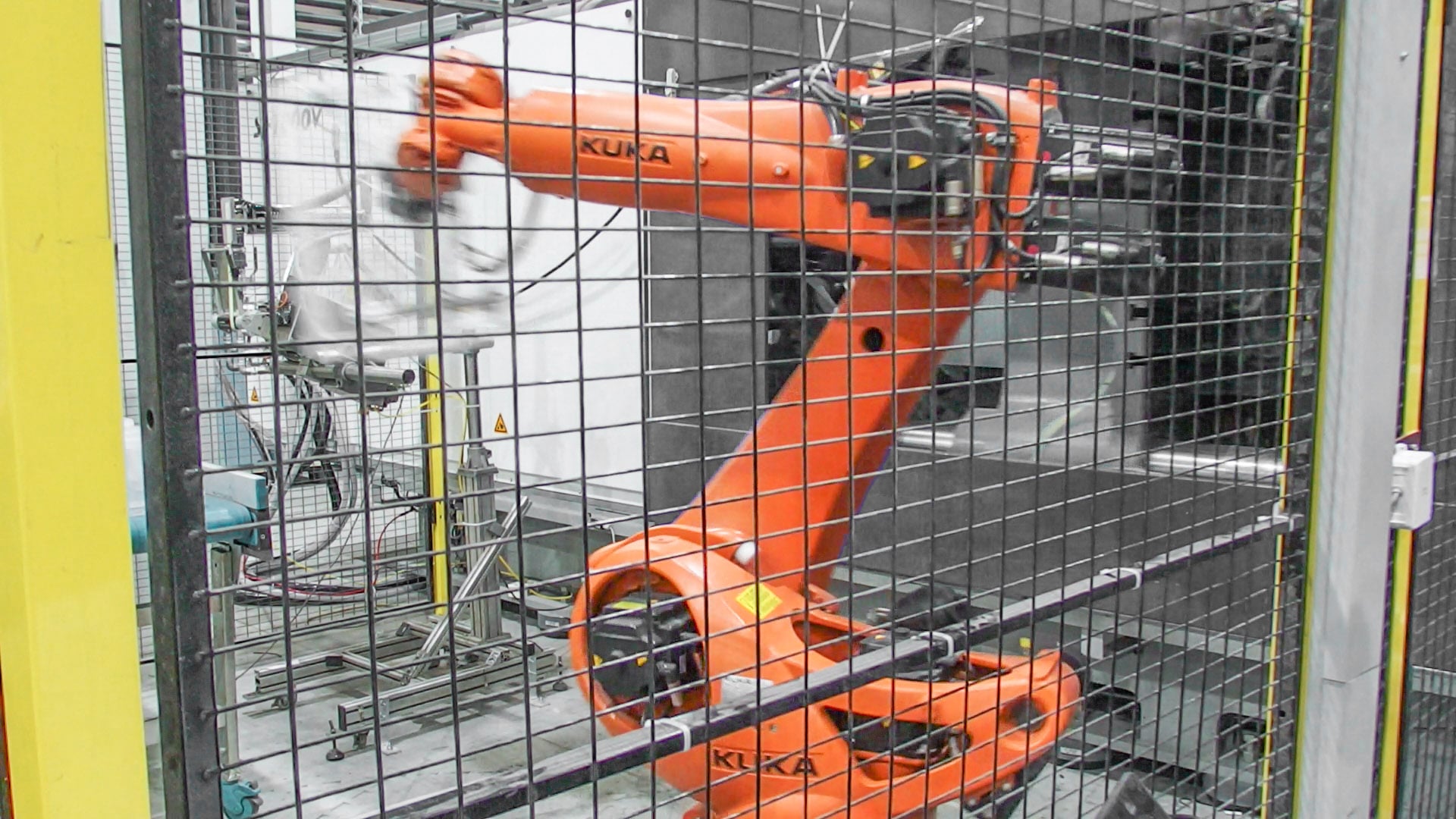

Design, production, installation of automatic and semi-automatic assembly stations, insert molding systems, and visual quality control stations.

Dedicated devices for the production of plastic products aimed at manufacturers of disposable laboratory, diagnostic, and pharmaceutical products.

Devices used in the technical industry, from components for the furniture sector, through household appliances products, to building elements.

- Products

uniLINE – Production flexibility, fast changeover, saving of production area, flat and cylindrical in one device.

Turnkey solutions – development of concept, documentation, delivery of equipment, and integration with the production line.

- Realizations

- About us

- Service

- Contact