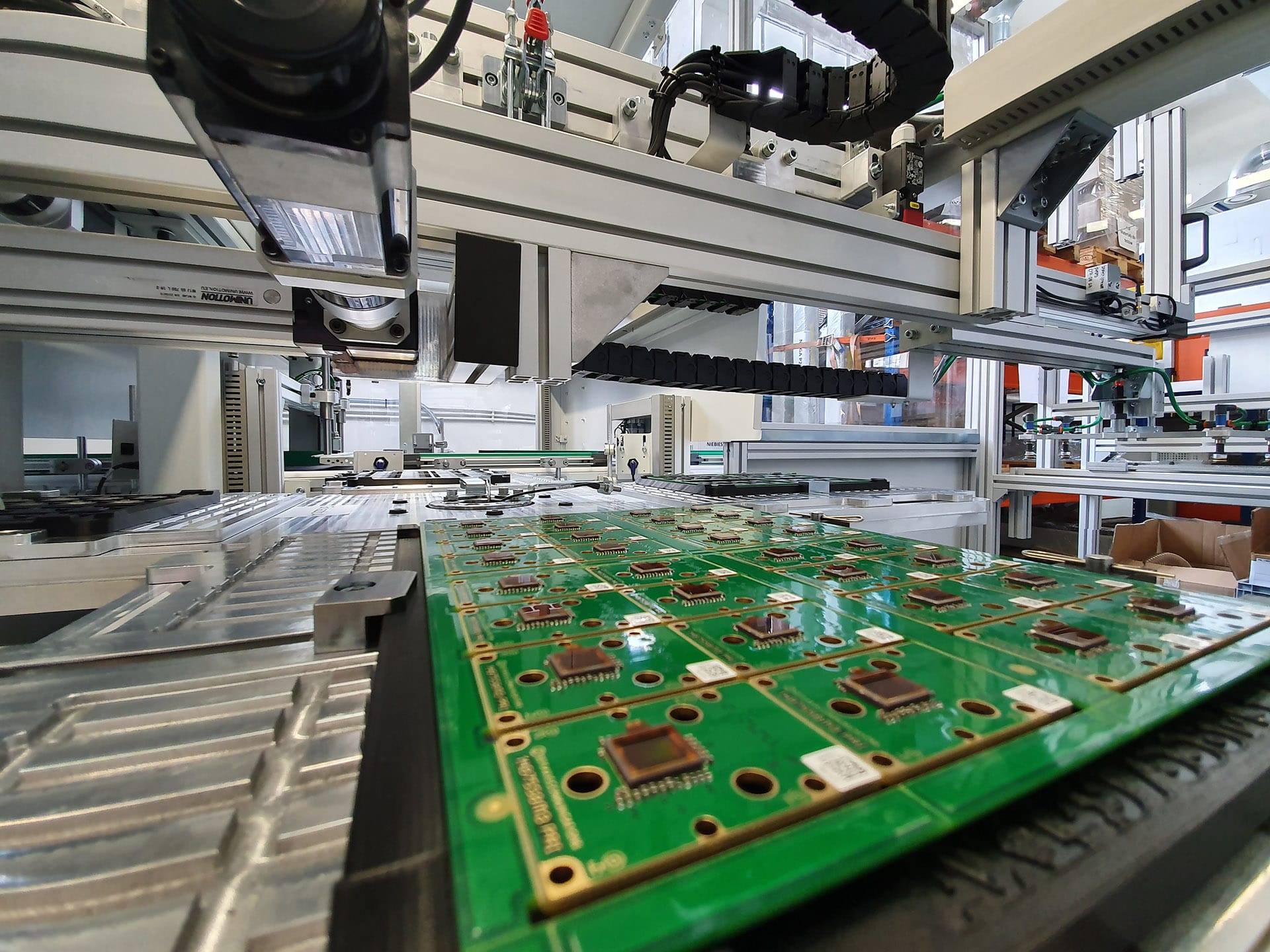

PCB assembly station with quality control and laser marking system is an advanced tool that enables the production of high-quality and customized products.

Above all, this station consists of several elements that allow for production from the assembly stage, through quality control, to laser marking.

In the first stage, PCBs are placed in special holders that provide precise and stable positioning during assembly. Then, electronic components are placed on the PCBs using specialized tools.

In the next stage, each PCB is subjected to detailed quality control, which includes checking the correctness of the assembly, the efficiency and durability of the connections, and the presence of any errors.

At the end of the process, each PCB is marked using a specialized laser marking system, which allows for the assignment of a unique code or logo for the customer, enabling full product identification.

The entire production process is carried out using traceability technology, which allows for monitoring and recording of each element, enabling full control over the entire process and allowing for quick and precise detection of any errors.

In this way, the PCB assembly station with quality control and laser marking system ensures high quality, personalized marking, and full product identification for the customer.