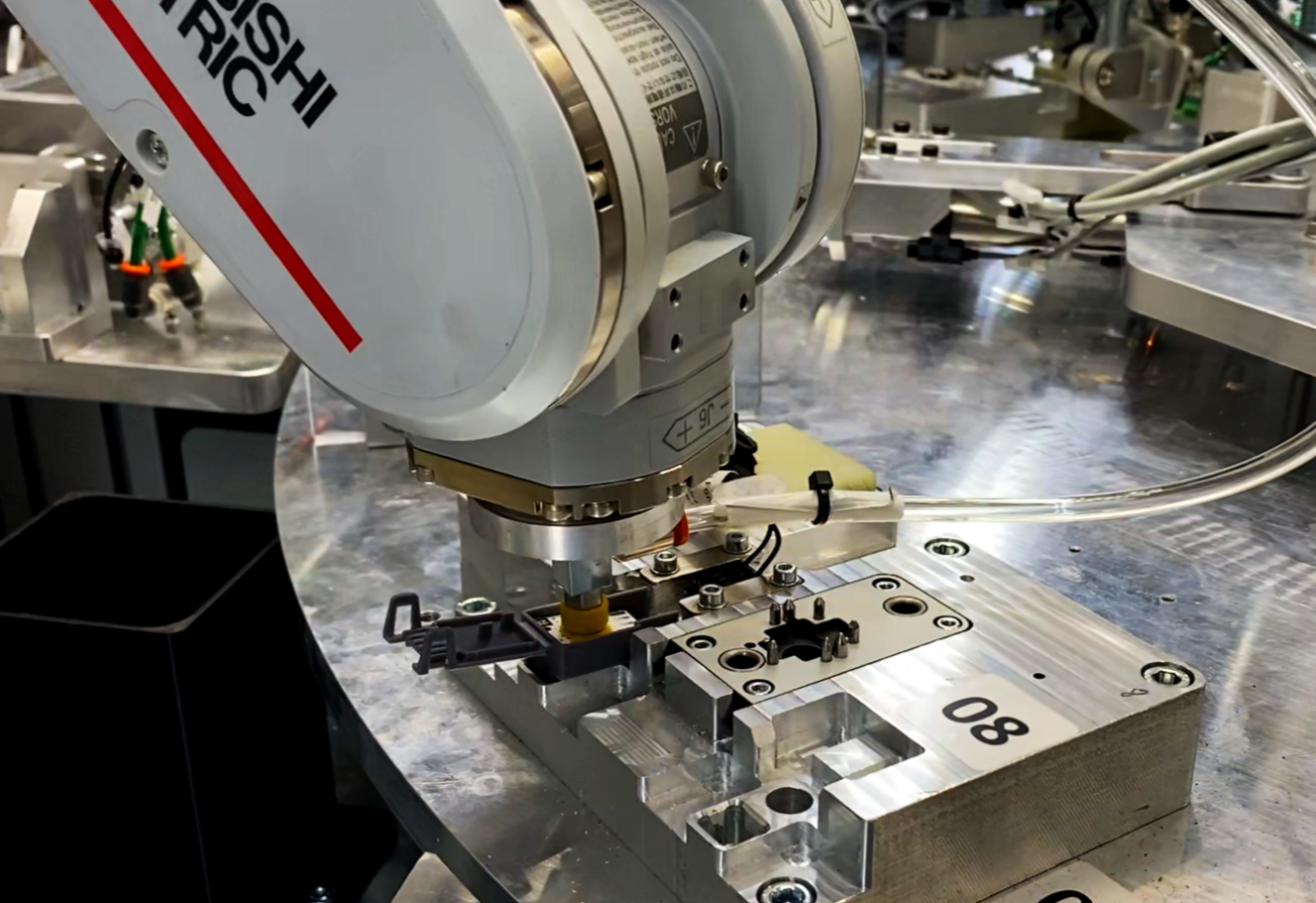

Automated electronic component assembly station for an automotive company. Inspection of details and traceability with human collaboration ensures high quality and repeatability of products.

Automated electronic component assembly station for an automotive company. Inspection of details and traceability with human collaboration ensures high quality and repeatability of products.

Equipped with 6 workstations, it enables fast production, where a workpiece is assembled every 8 seconds, with quality control to ensure excellent quality. Traceability is an important element, enabling the tracking of parts from production to delivery. Thanks to the Mitsubishi 6-axis robot used, the device guarantees precise assemblies and dedicated stations for different products guarantee repeatability of processes. CE compliant compact design is a space saver on the production floor .