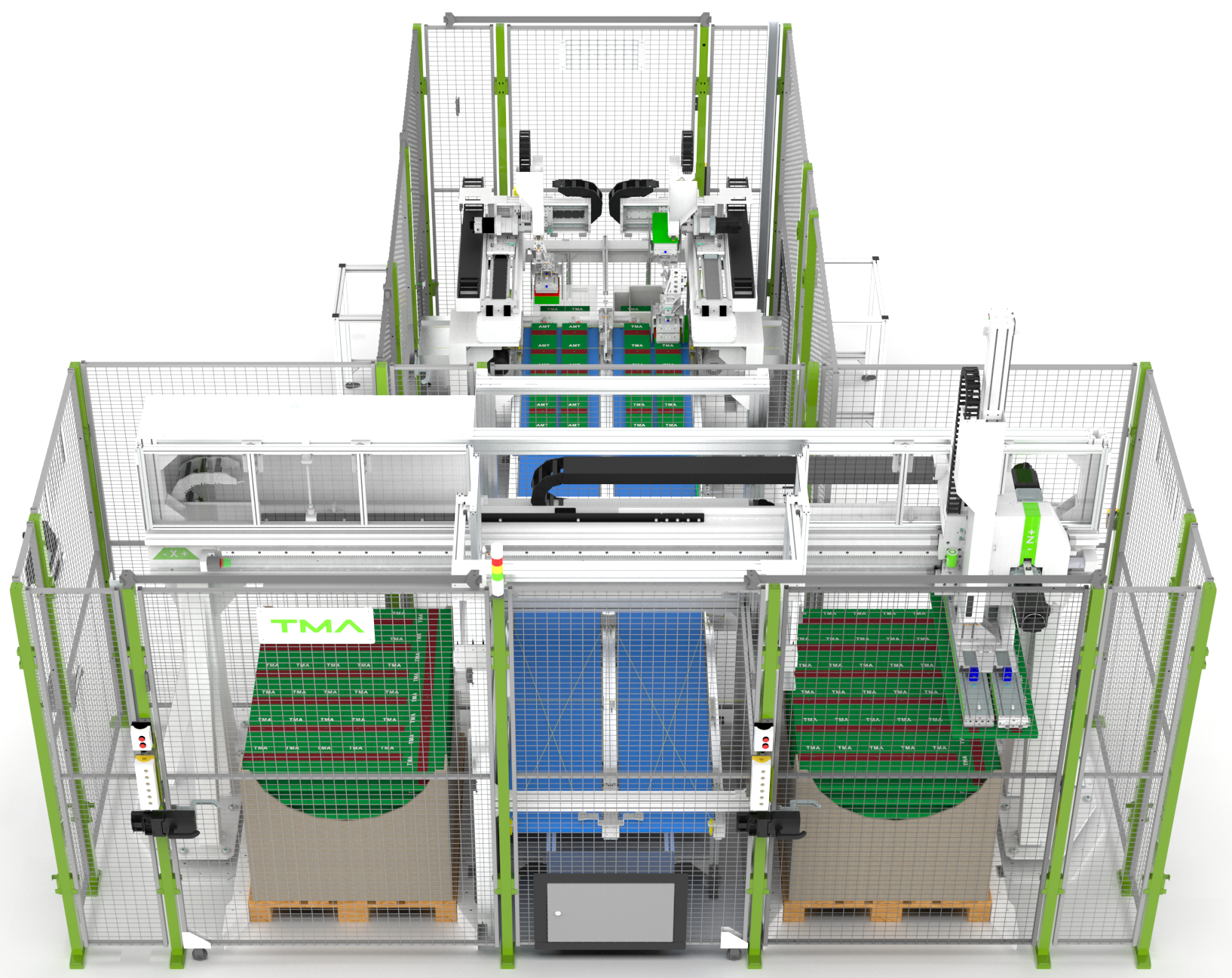

Station for depalletizing and automatically loading workpieces into cartons. Fully automatic process for maximum efficiency. Compact design with minimal space requirements.

Station for depalletizing and automatically loading workpieces into cartons. Fully automatic process for maximum efficiency. Compact design with minimal space requirements.

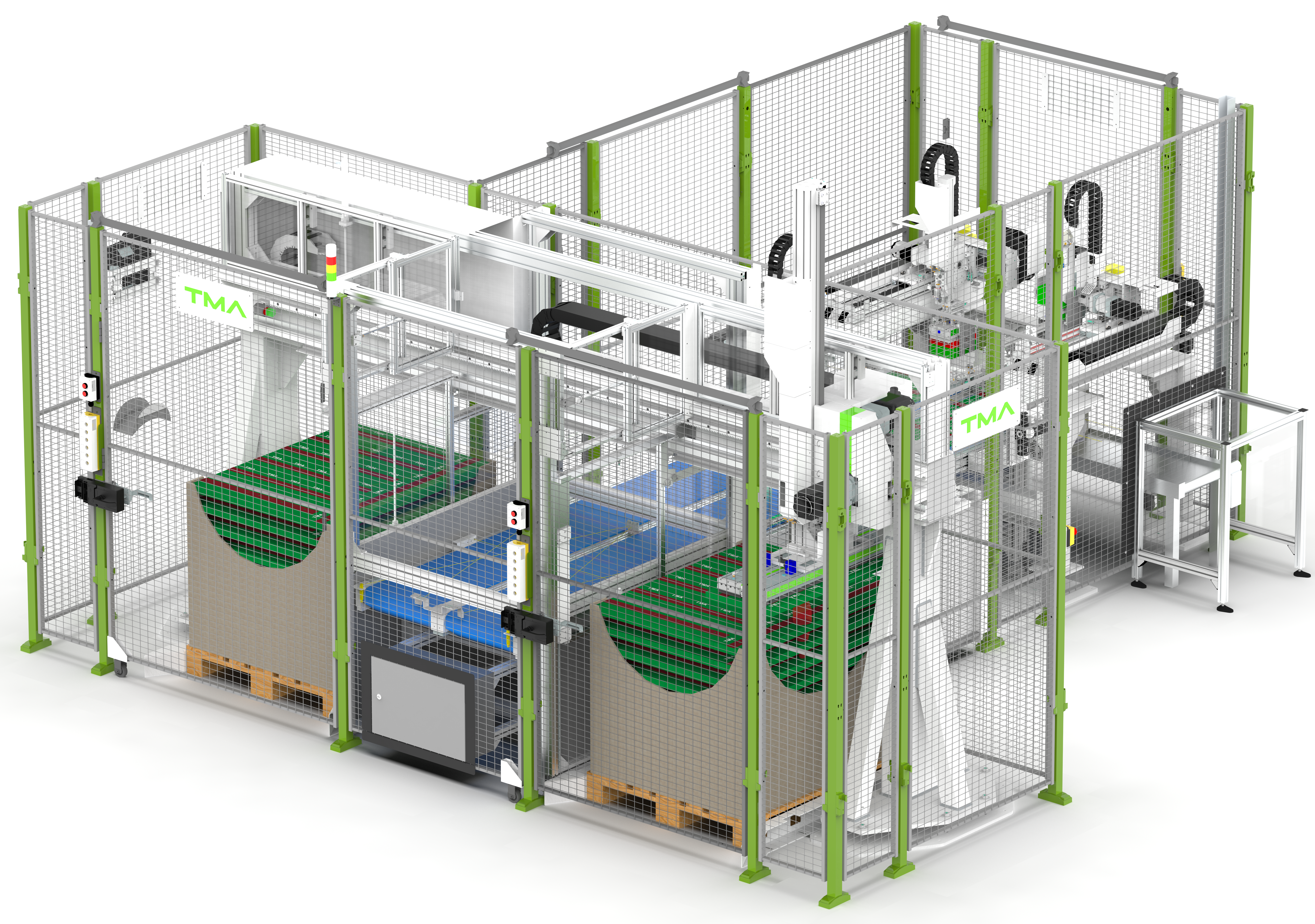

One of our equipment is an advanced depalletizing station for depalletizing from containers on pallets and loading workpieces into cartons. This innovative solution was designed specifically for a customer in the packaging industry, with the goal of maximizing process efficiency and fluidity.

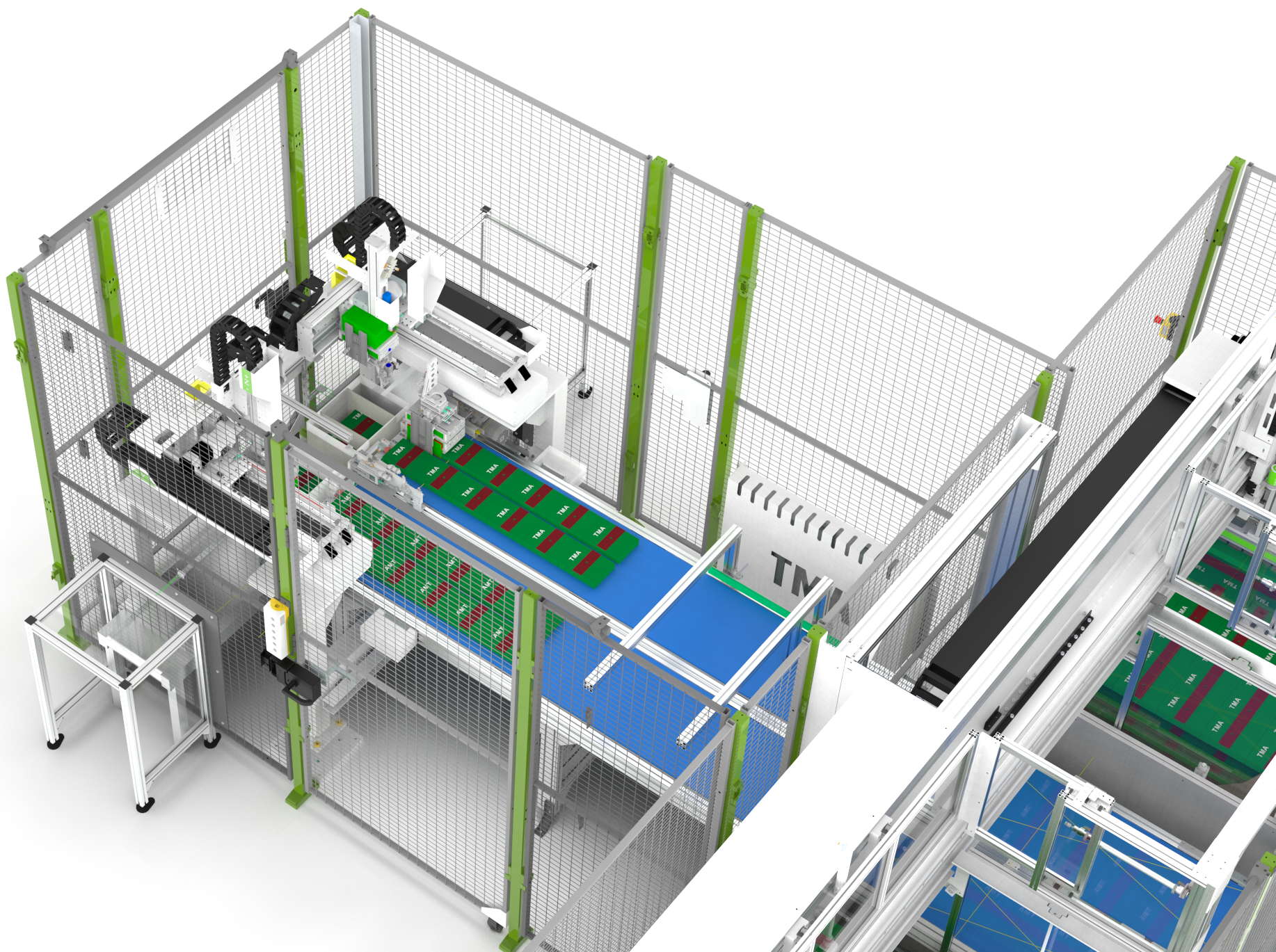

Our station uses a large Cartesian robot that translates workpieces from pallets to a wide belt conveyor. The transporter delivers the workpieces to a location where two small robots place them individually in cartons. Before the workpiece is loaded, the carton is scanned to retrieve information on how many workpieces are to go in it. As a result, the system can handle a variety of cartons that arrive in random order.

The station is equipped with two places for inserting a pallet of workpieces, which allows continuous operation without downtime. When one pallet is replaced with a new, full pallet, the robot continues to retrieve details from the other. The machine stacks individual workpieces into cartons every 1.4 seconds, ensuring high productivity and reliability.

TMA AUTOMATION has specialized for years in designing and constructing advanced palletizing and depalletizing stations. In this particular case, we were able to combine both depalletizing and loading functions in one integrated station, ensuring maximum efficiency and reliability.

With our position, our customers can significantly increase their productivity, improve the quality of their processes, and reduce operating costs. Innovation and reliability are the foundations on which we base our solutions, which meet the highest industry standards.

We believe in the power of innovation and reliability. Our advanced technologies help companies reach new levels of production efficiency and quality. Join the companies that have already benefited from our cutting-edge solutions and see how our devices can improve your business.