Magnetically driven IML station for a customer in the packaging industry. Fully integrated solution for superior performance. Compact design with minimal space requirements.

Magnetically driven IML station for a customer in the packaging industry. Fully integrated solution for superior performance. Compact design with minimal space requirements.

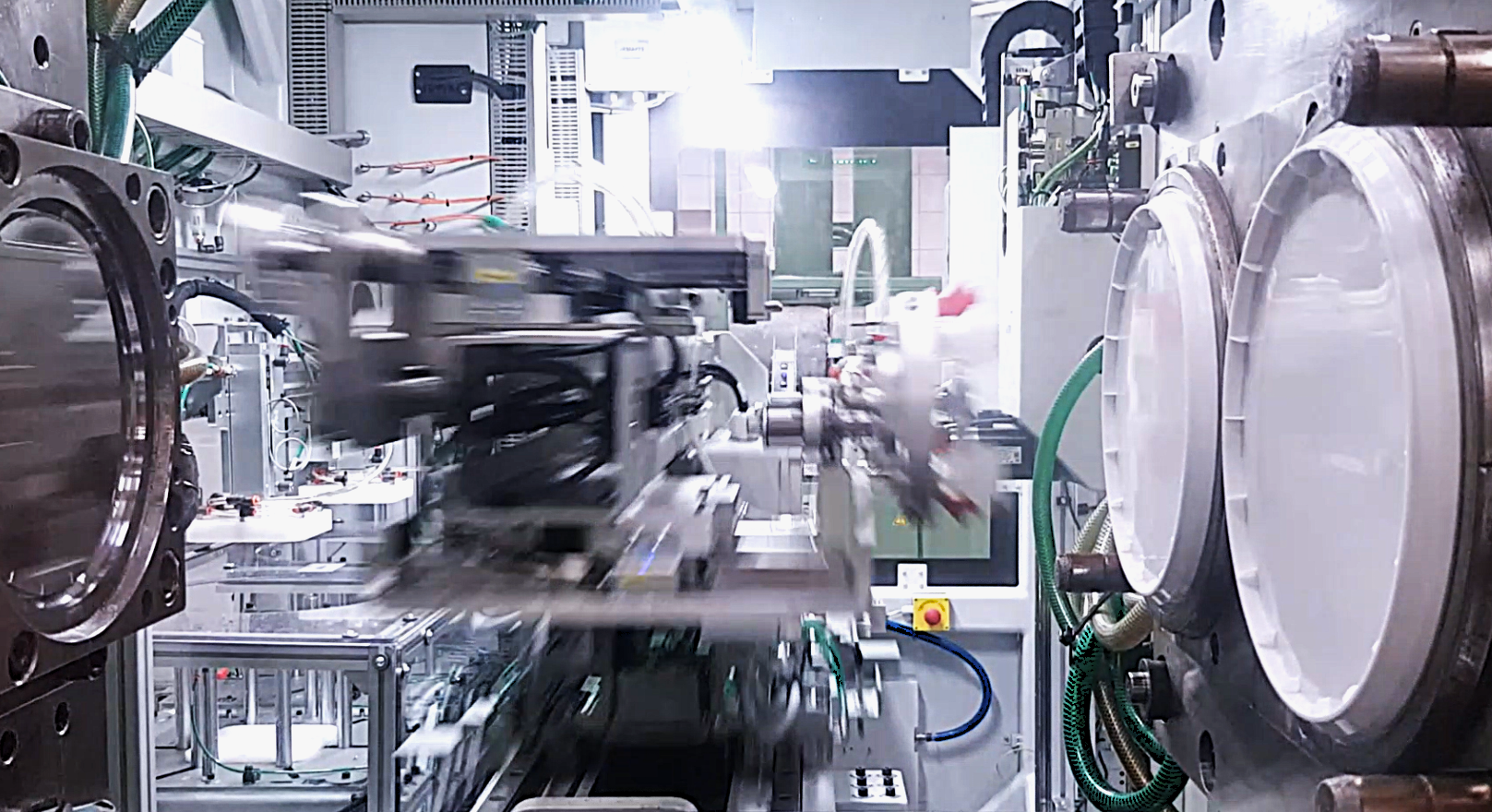

One of our newest pieces of equipment is an advanced in-mold labeling station for plastic products using IML (In Mold Labeling) technology. This innovative solution was designed specifically for a customer in the packaging industry, with the goal of maximizing production efficiency and precision.

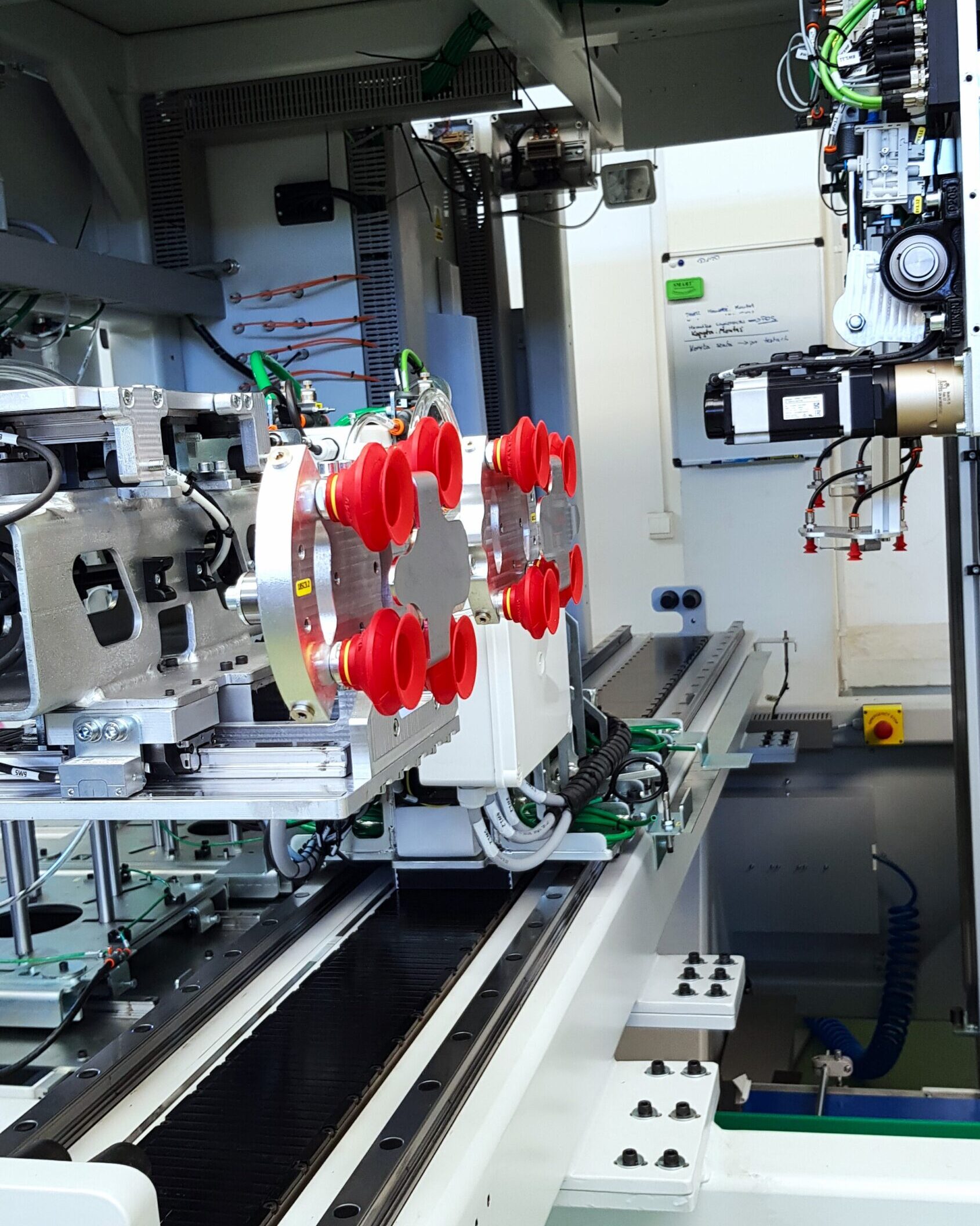

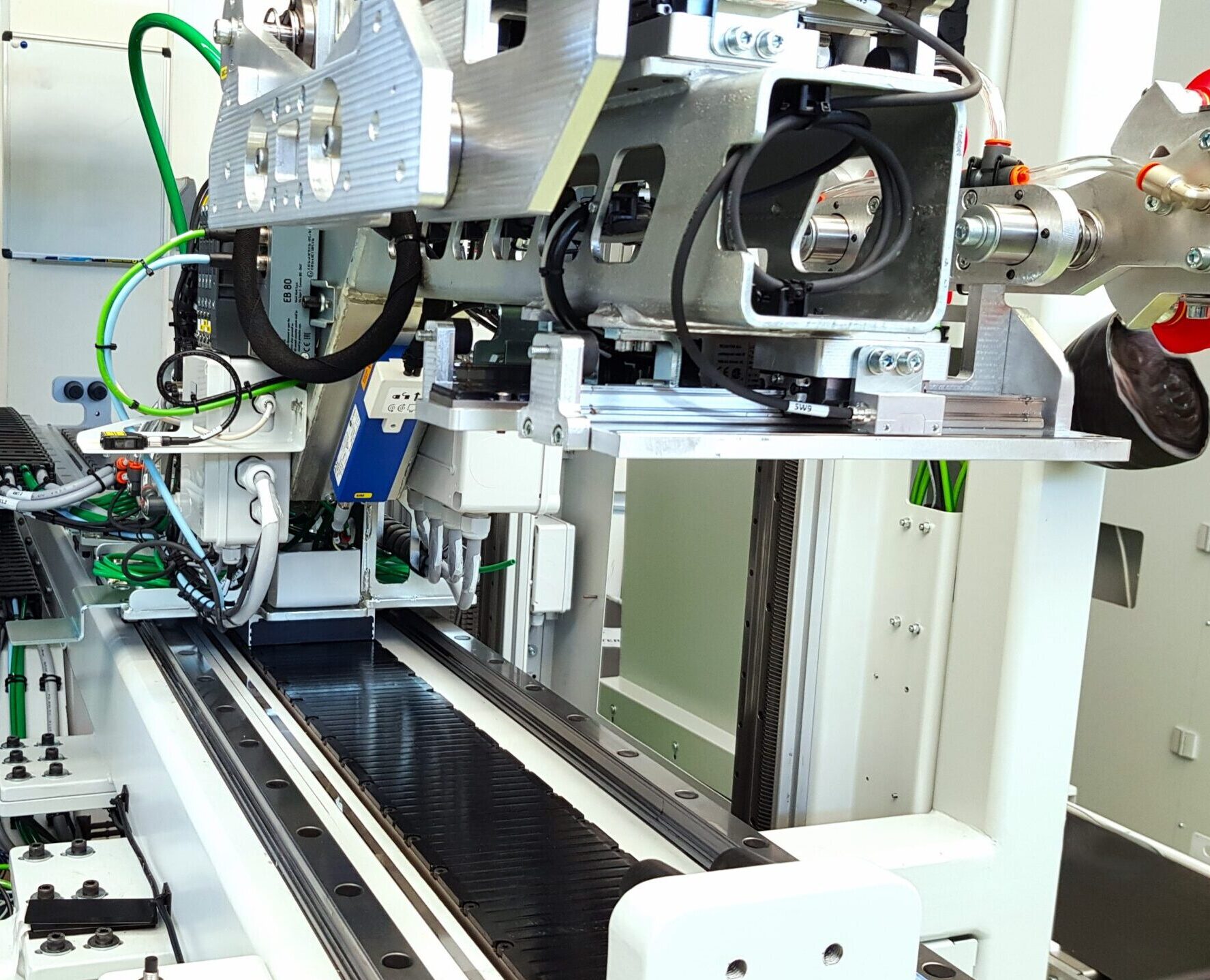

Our station works at a plastic injection molding machine, operating a double injection mold. The robot, which is responsible for receiving workpieces from the mold and inserting labels, is characterized by exceptional speed – the entire cycle takes only 6 seconds, of which the process of receiving workpieces and inserting labels alone takes only 1.3 seconds.

This remarkable speed is made possible by the magnetic drive, which significantly outperforms standard drives in terms of reliability, speed of operation, precision and quietness of operation. This makes the stand ideal for companies in the packaging industry that are looking for efficient and precise production systems.

Features that guarantee the highest quality and efficiency in production:

With our IML stand, companies in the packaging industry can significantly increase their productivity, improve quality, and reduce production costs. At TMA AUTOMATION, we always focus on innovation and reliability, providing solutions that meet the highest industry standards.

Our many years of experience in designing and constructing IML workstations allows us to provide equipment that not only meets but exceeds our customers’ expectations. We invite you to cooperate with us and join the ranks of satisfied customers of TMA AUTOMATION.