IML uniLINE station for labeling, decorating injection molded products. Production flexibility through rapid tooling changes

IML uniLINE station for labeling, decorating injection molded products. Production flexibility through rapid tooling changes

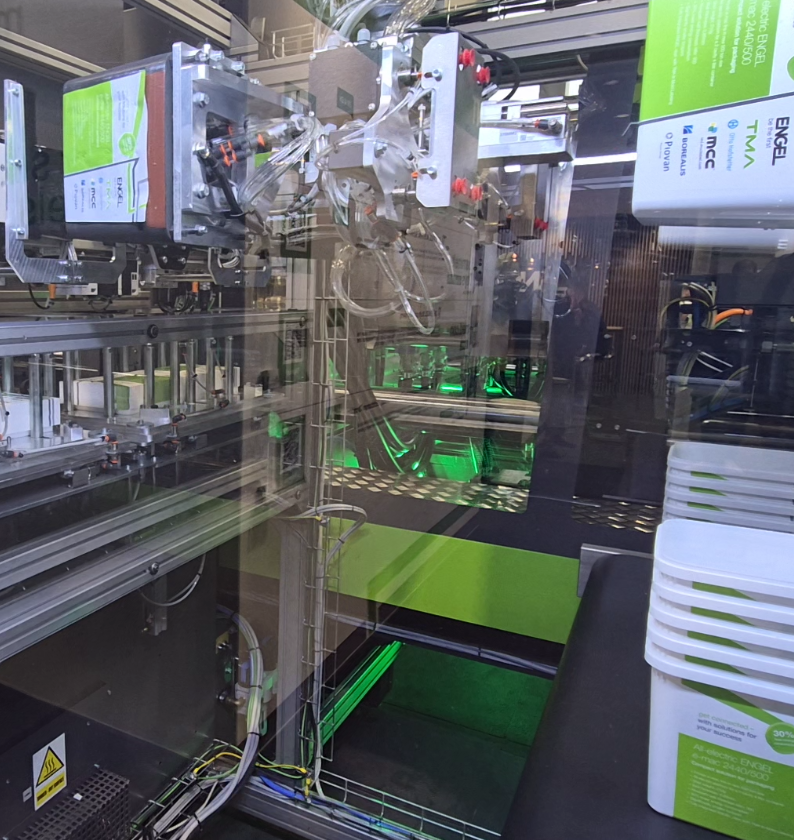

IML uniLINE, an innovative workstation designed for high flexibility and efficiency in rapidly changing production. Our IML (In Mold Labeling) technology solution, provides precise and permanent decoration or labeling of plastic products right from the injection molding stage. This is an excellent option for companies that produce a variety of packaging products and are looking for equipment that enables seamless transitions between different types of production. Interchangeable components of the station, such as label magazines, label feed grippers, stacking system grippers, and a Cartesian robot gripper, can be easily adapted to new parts – for example, changing production from buckets to lids or switching from a flat label to a cylindrical label. Replacement mechanisms developed by TMA Automation ensure that the machine can be quickly and efficiently adapted to current production needs.

Easy replacement of production components:

Precision IML labeling:

Compact design: