We are a company that has been designing, manufacturing and installing robotic workstations and production lines for the automotive industry for many years. Our offer includes both automatic and semi-automatic assembly stations, insert systems for injection molds and quality control vision stations. Our company stands out for its extensive experience in the plastics processing industry, which allows us to provide effective advice to customers at the stage of designing injection molds. This enables us to design solutions that enable seamless automation of the production process.

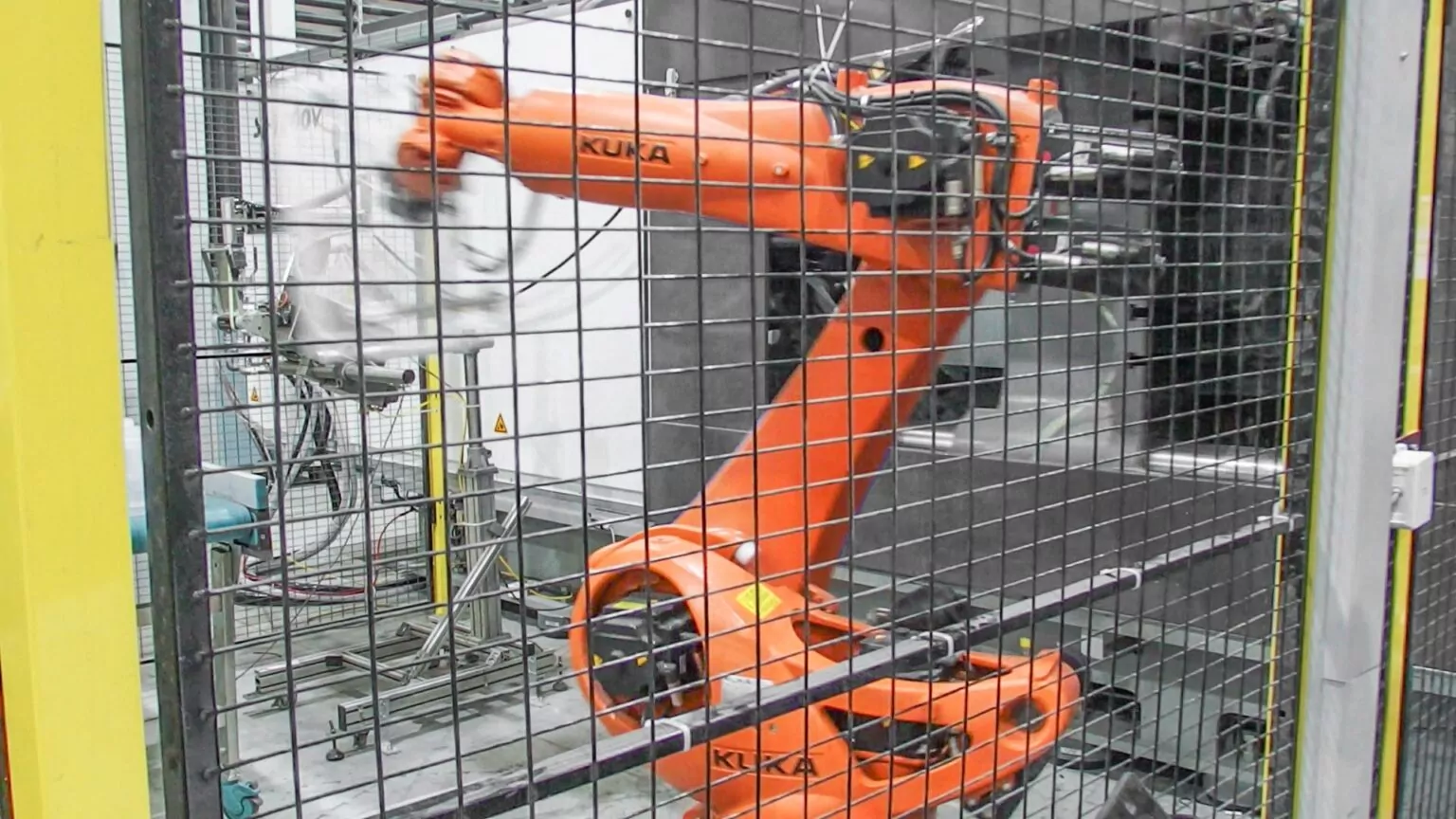

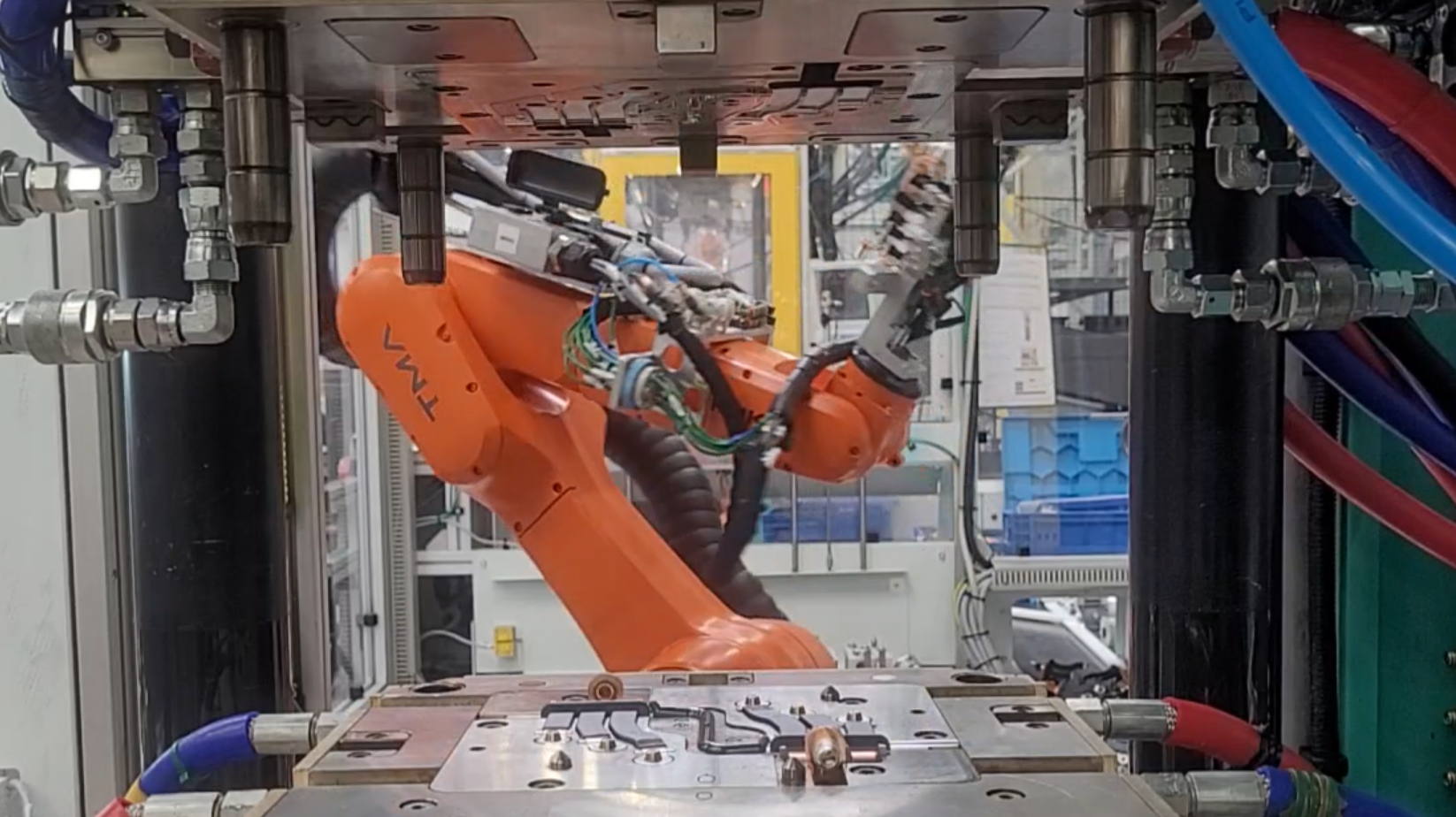

A KUKA robotic insert feeding station for precise insertion of plastic injection molding parts. The KUKA robot is designed for maximum efficiency and precision, achieving high quality products

The bench uses quality control systems to thoroughly inspect each component after injection molding. This makes it possible to detect any defects and respond quickly to any problems.

After injection molding, each part is marked with a special marking system and the use of a tracebility system makes it possible to trace the production history of each part, which is especially important for products that require accurate identification and tracking.

We are at your service.

We will be happy to help you choose the best solution.