INNOVATIVE IML STATION FOR THE PACKAGING INDUSTRY ADAPTED TO THE CUSTOMER’S UNUSUAL REQUIREMENTS. FOUR LABELS ON ONE DETAIL

INNOVATIVE IML STATION FOR THE PACKAGING INDUSTRY ADAPTED TO THE CUSTOMER’S UNUSUAL REQUIREMENTS. FOUR LABELS ON ONE DETAIL

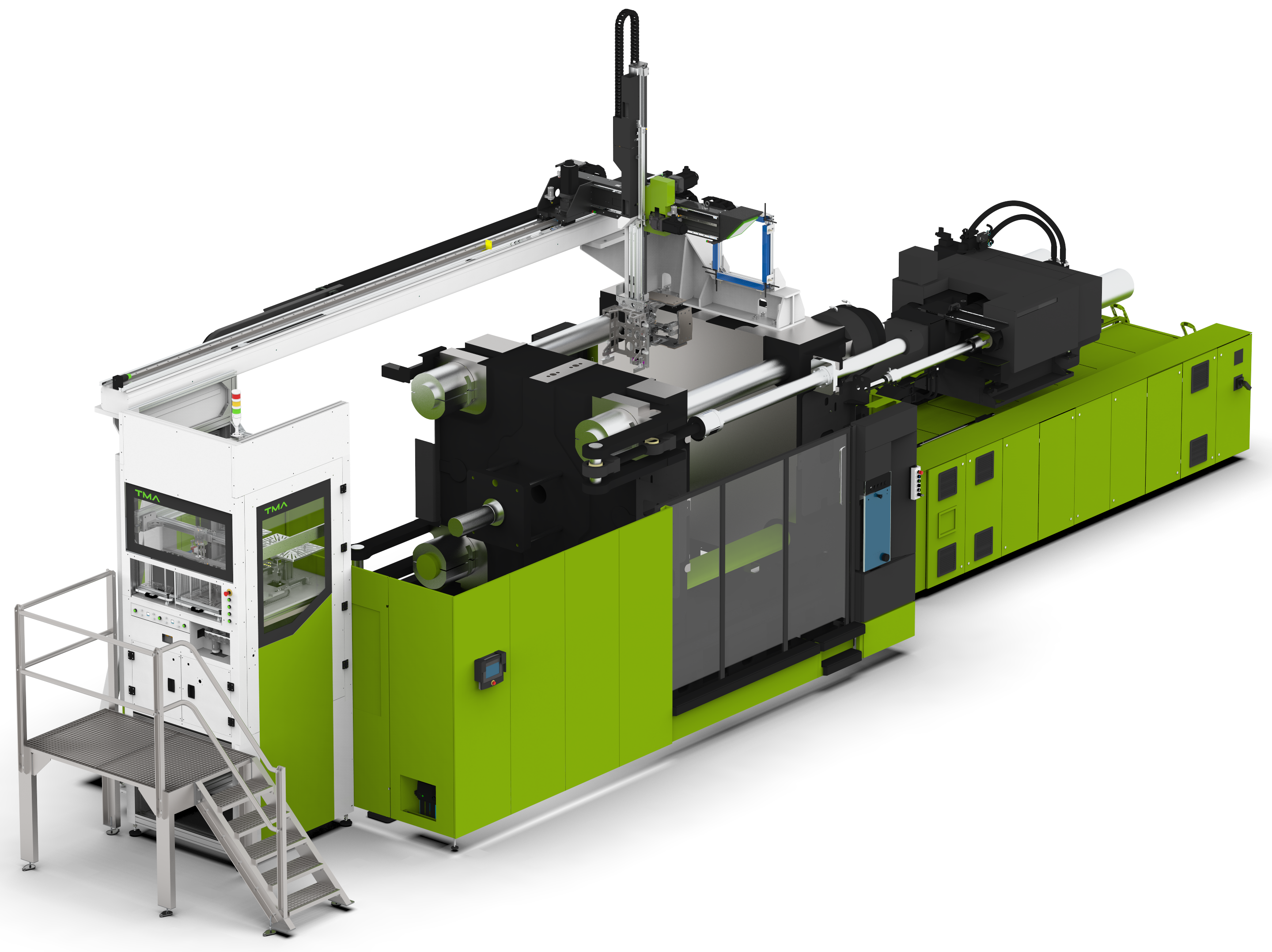

Presenting an advanced in-mold labeling station for plastic products using IML (In Mold Labeling) technology. This groundbreaking solution was designed to meet the specific requirements of a customer in the packaging industry, taking into account the unusual arrangement of equipment on the production floor. The station runs alongside the injection molding machine, an unusual setup, but one that is ideally suited to the customer’s production conditions. A special Cartesian robot has been developed to operate this station, ensuring precise and fast operation. In the labeling process, four labels are inserted into the injection mold, although only one part is produced – a very large box. This unique solution makes it possible to produce large and complex parts with high efficiency.

Translated with DeepL.com (free version)

Thanks to our IML station, companies from the packaging industry can significantly increase their efficiency, improve the quality and appearance of their products and reduce production costs. At TMA AUTOMATION, we always focus on innovation and reliability, providing solutions that meet the highest industrial standards. Our experience in designing and constructing IML stations allows us to offer devices that adapt and meet the expectations of our customers. We invite you to cooperate and use TMA AUTOMATION’s innovative technologies that bring real benefits to business.