TMA company offers a wide range of palletizing robots designed for palletizing and depalletizing various products.

One task, many possibilities

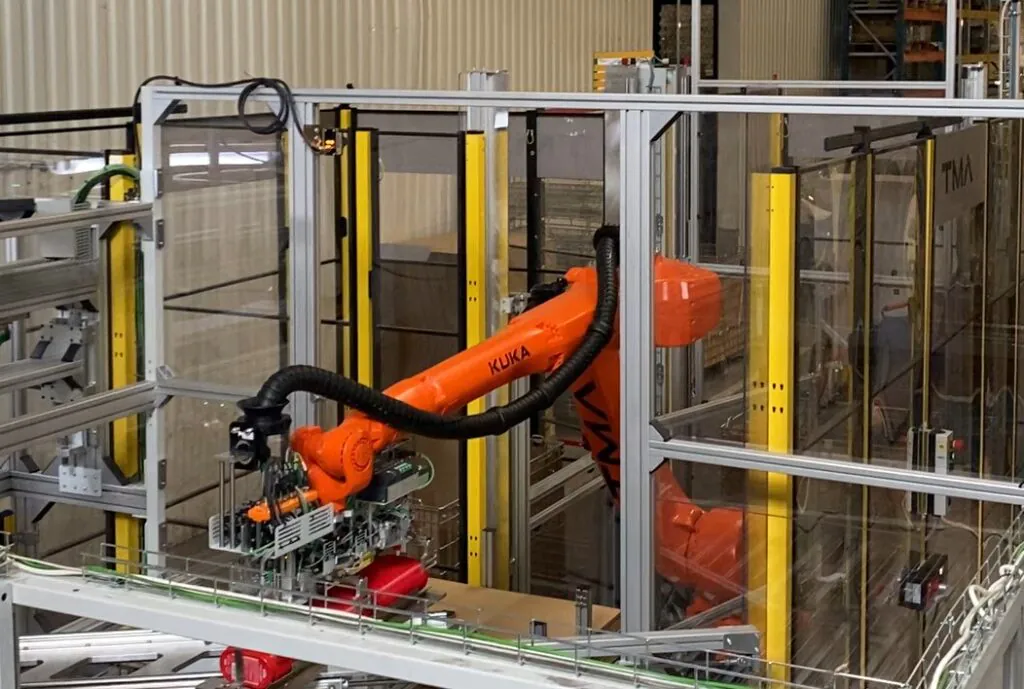

For palletizing, we use our own Cartesian robots and six-axis robots.

We are at your service.

We will be happy to help you choose the best solution.

• Support for picking different-sized parts

• Servomotors on all axes (including the rotational C axis)

• Fencing to prevent any operator contact with the robot

• Portable remote control for robot programming

• Loaded pallet dispatch station (optional)

• Pallet magazine with automatic feeding

• System for feeding cardboard spacers between layers

Stroke | |

|---|---|

X axis | 1800 mm |

Y axis | 1300 mm |

Z axis | 1800 mm |

R axis | 0-90° (optionally: 0-360°) |

Load capacity | |

|---|---|

gripper + load | 10-20 kg |

Drive | |

|---|---|

X axis | servomotor, gear rack |

Y axis | servomotor, gear rack |

Z axis | servomotor, belt drive |

R axis | pneumatic (optionally: servomotor) |

part picking | vacuum pump / jaw gripper |

Options | |

|---|---|

Spacer feeding system | YES |

Automatic pallet feeding | YES |

Automatic pallet retrieval | YES |

Other | Programmable inputs | 8 |

|---|---|

Programmable outputs | 8 |

• System for feeding spacers between box layers

• Non-stop operation available in configurations with 2 or more pallets

• Mechanical curtains prevent operator contact with the robot during pallet exchange

Stroke | |

|---|---|

X axis | 3400 mm |

Y axis | 1300 mm |

Z axis | 1800 mm |

R axis | 0-90° (optionally: 0-360°) |

Load capacity | |

|---|---|

gripper + load | 10-20 kg |

Drive | |

|---|---|

X axis | servomotor, gear rack |

Y axis | servomotor, gear rack |

Z axis | servomotor, belt drive |

R axis | pneumatic (optionally: servomotor) |

part picking | vacuum pump / jaw gripper |

Options | |

|---|---|

Spacer feeding system | YES |

Automatic pallet feeding | YES |

Automatic pallet retrieval | YES |

Other | Programmable inputs | 8 |

|---|---|

Programmable outputs | 8 |

Advantages