IML uniLINE – production flexibility

IML uniLINE station for labeling, decorating injection molded products. Production flexibility through rapid tooling changes

INNOVATIVE IML

INNOVATIVE IML STATION FOR THE PACKAGING INDUSTRY ADAPTED TO THE CUSTOMER’S UNUSUAL REQUIREMENTS. FOUR LABELS ON ONE DETAIL

Depalletization and carton packing

Station for depalletizing and automatically loading workpieces into cartons. Fully automatic process for maximum efficiency. Compact design with minimal space requirements.

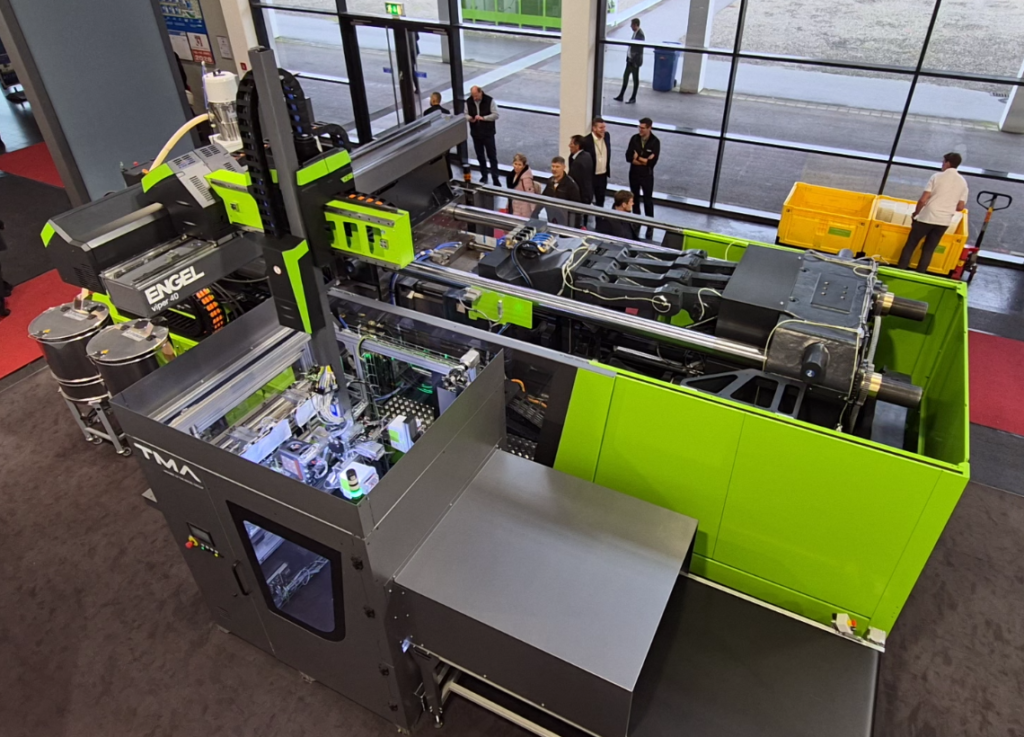

IML SpeedLINE – Fast in-mold decoration

Magnetically driven IML station for a customer in the packaging industry. Fully integrated solution for superior performance. Compact design with minimal space requirements.

Assembly and test line

Assembly line with test benches made for an automotive customer. Fully controlled process with traceability. A series of processes encapsulated in a compact design.

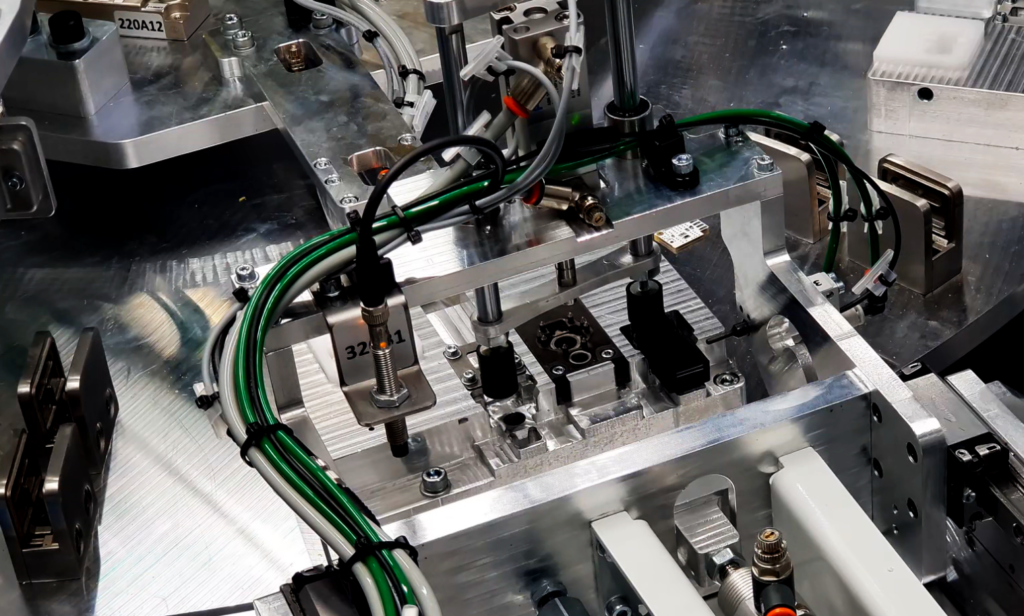

Assembly of electronic components

Automated electronic component assembly station for an automotive company. Inspection of details and traceability with human collaboration ensures high quality and repeatability of products.

Petri dish collection station

Automatic stapler and nailer

The wood nailing and stitching device is a versatile tool that allows you to effectively connect various wooden elements, such as fences, panels, walls, grids and strips.

DWP tile filling and packaging line

A device for filling, packing and stacking DWP plates made for a Polish company from the medical industry. It operates in accordance with the Clean Room ISO7 standard, ensuring a high level of air cleanliness in the production environment.

Palletization of cans

The fish can stacker with two stations uses a 6-axis robot and a mechanism that changes the orientation of the can stacks. The cans are stacked vertically, which then have to be rotated 90 degrees to change their orientation from vertical to horizontal. This step is necessary to allow easy stacking of the cans in […]